Office of Naval Research

ONR

Physics Deep-link and Digital Twin for Structural Health Monitoring of Naval Structures

Duration: 2024-2027

Role: PI

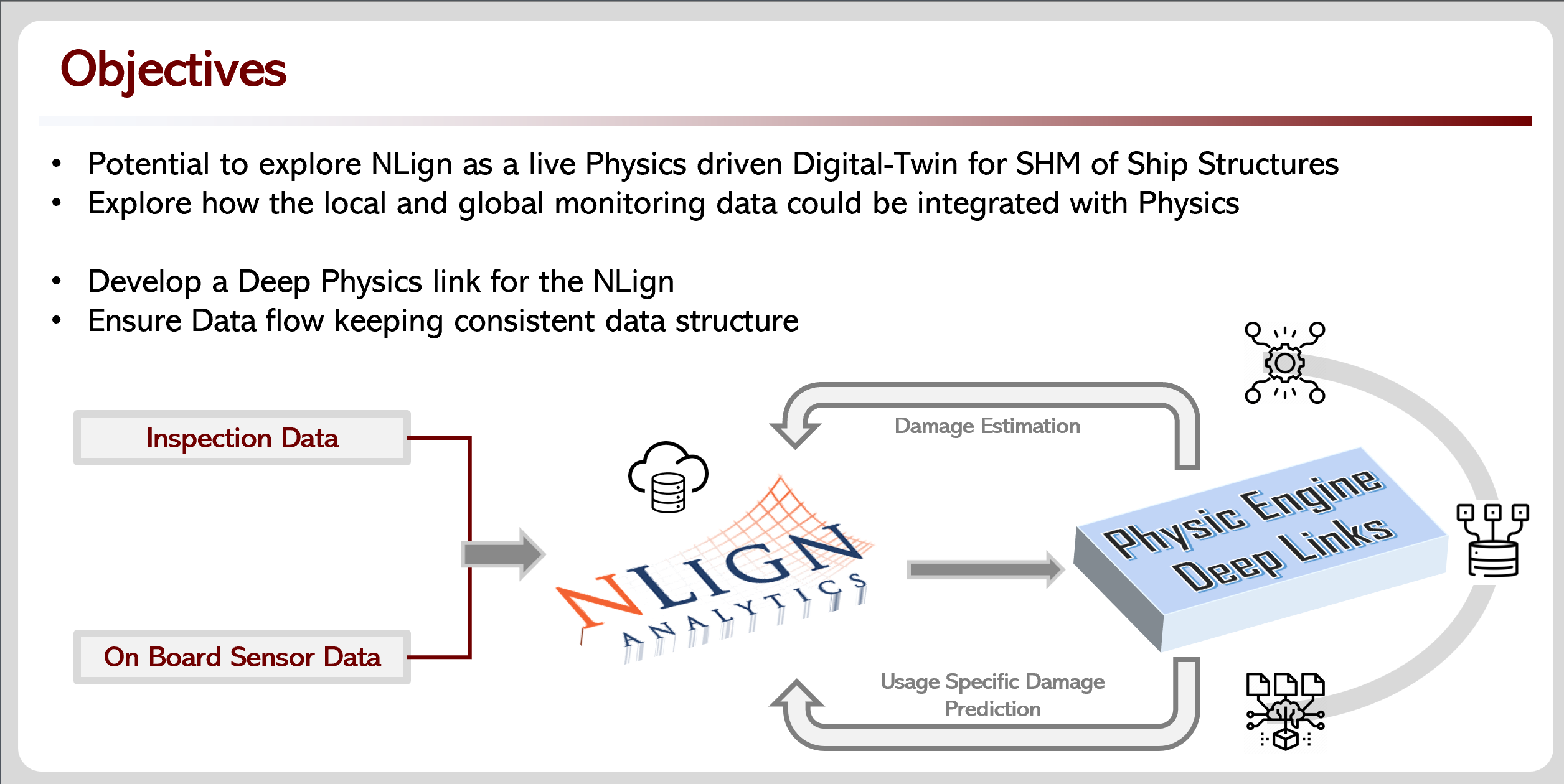

State-of-the-art Digital-Twin for real time assessment of structural health and estimating the reliability of the structural operations is far from its realization. Digital-Twin is envisioned in a way where it should be able to perform the real time assessment of the responses from the existing and new naval structures. Visualization, estimation, and prediction of the structural health of the naval structures will be critical for the future manned or unmanned naval fleets through integrated sensory system coupled with their Digital-Twin. Physics based understanding of the sensory data from new generation of material systems with existing and new sensor system is utmost important for seam less functionality of the Digital-Twin. However, due to several bottle neck challenges, this goal is obscured. Currently no physics-based link exists with the Digital-Twins of Naval assets that can derive intelligent decision form the sensor data in real time. Hence, the project objective is to create a universal physics-deep-link for the Digital Twins of naval assets with existing and new material systems. We propose a close collaboration and continuous interaction with NSWC Carderock’s material and SHM team with our undergraduate and graduate students to create a universal Physics Deep link interface that could easily interface with Navy’s current Digital Twin software. The proposed physics deep-link will be developed through extensive computational and experimental study that will house trained machine learning (ML) models and artificial intelligence (AI) for real time damage estimation and prediction in naval structures. While contributing to the scientific merit we propose to achieve additional broader impact through training and education of our students using a unique Expose, Engage, Educate and Evaluation (E4) model towards the development of workforces for the future Navy.

Digital Twin 4.0: Demonstration of Integration of Physics based Analysis Tools with a Digital-Twin for Structural Safety

Duration: 2022-2023

Role: Research Fellow

Project Objective: This project was performed during the sabbatical at NAVSEA, Carderock, MD. First objective was to find the immediate bottleneck need to mature the Digital-Twin for SHM. As currently realized, state-of-the art Digital-Twins for estimating structural reliability and health assessment are far from achieving the wide-ranging capabilities for digital transformation. To inform mission planning and act as an authoritative source of truth for engineering analyses, sensor data to diagnose structural health, physics-based models, and ML are to be fused to provide real time estimates of local and global reliability of structural components and structures as a whole. However this grand vision is yet to be materialized due to multiple technological, engineering, and cultural work flow challenges. This project was to identify and propagate the concept of the new generation four level Digital-Twin 4.0.

Digital Twin for Online SHM of Naval Structures

Duration: 2021 | 2022

Role: Summer Faculty Fellow

Project Objectives: Create ML algorithm to predict crack growth in specific naval structural component from ultrasonic Guided wave data generated using Piezoelectric sensors. Algorithm was developed using training data from existing data set collected over time.

SHM System Development for Detection of Corrosion in HSV Ship Hulls made of 5xxx Aluminum

Duration: 2010-2012

Role: PI

Project Objective: Prof. Banerjee served as PI on this project which was a SBIR Phase I - II project funded to Acellent Technologies Inc. Objective was to develop phase array capability of PZT based Guided wave SHM system to detect corrosion in corrosion prone zones by artificially focusing Guided wave beams. It was not possible to put sensors every where. Hence, the study included optimized placement of clustered sensor for maximum coverage of scanning area.