Key Equipment

Lynx Automated Fiber Placement Machine

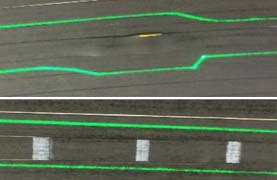

Automated Composites Structure Inspection System (ACSIS)

Humm3 Heating System

Composite Autoclave

Composite Oven

Compression Molding Machine (Hot Press)

Induction Welder

MFMS has access to cutting-edge equipment enabling researchers to

develop engineered materials for industrial applications.

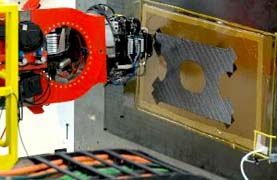

Lynx Automated Fiber Placement Machine

The Ingersoll Machine Tools Lynx AFP machine is used for the development of manufacturing methods for large composite structures.

- The system at the McNAIR Center is capable of working with thermoset, dry fiber, and

thermoplastic material systems. - The machine can layup 16, ¼ inch tows of carbon fiber between 40 - 60 meters per

minute for representation production level environment standards. - The Lynx is a 6 axis system, with 7th axis rotatory positioner, capable of working with

flat, double curved, and cylindrical tool geometries. - Maximum work envelope is 2150mm x 1524mm x 5000mm

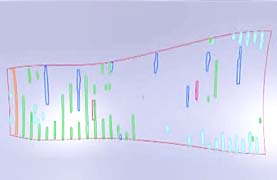

Automated Composites Structure Inspection System (ACSIS)

ACSIS is developed by Ingersoll Machine Tools for the inspection and automated defect detection of fiber placed composite parts.

- ACSIS automatically inspects, detects, and maps the most common composite defects

and can be trained to detect further defects as necessary. - Current ACSIS scan speed is up to 120 m/min for detection defects from AFP layups.

Composite Oven

The Composites Oven at McNAIR is manufactured by Wisconsin Oven Corporation and is used for curing of thermoset material systems, consolidation of thermoplastic material systems, infusion of dry fiber material systems within oven during operation.

- The composites oven is fitted with an advanced elevated temperature infusion system

integrated by the McNAIR Center. - Additional specifications for the composites oven include: 6ft x 6ft x 10ft working space,

maximum operating temperature of 800℉, 4 vacuum ports with transducers and port

monitors, 24 thermocouple jacks for temperature monitoring of parts during oven

operation, electric based heating.

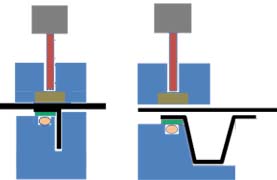

Compression Molding Machine (Hot Press)

The Compression Molding Machine at McNAIR is from Wabash and is used for curing of thermoset material systems, consolidation of thermoplastic material systems, and thermoforming of material systems.

- The compression molding machine is capable of temperatures up to 800°F and force up

to 50 tons. Maximum workspace capability of 20” x 20” x 6” - Molds currently available:

- Flat Plate Picture Frame (12” x 6”)

- L-Stiffener (6” length with 1” flanges)

- Omega-Stiffener (6” length and 4” height)

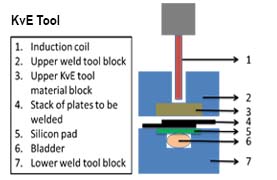

Induction Welder

The induction welder at McNAIR are used for the heating and fusion bonding of composite material systems, specifically thermoplastic composites.

- The induction welder can be used for fusion of both carbon fiber and glass fiber

reinforced composites. - Major Welding Equipment available for the Induction Welder are as follows:

- Ambrell Induction Heaters

- EasyHeat (10kW power)

- EkoHeat (45kW power)

- KUKA Robot

- KvE Induction Welding Tool and Coil

- Automated Data Acquisition Software and Tower